We are here for the changemakers.

Those who see the world not as it is but as it could be. The ones with the potential to transform life science into something life-changing.

Our mission is to accelerate research and startups to realize the boldest ideas for better human and planetary health ahead of the curve, taking them from A to B, from Academia to Business.

So, let’s catalyze sustainable impact and accelerate a better world together.

Let's bring science to life.

Do you want to bring science to life?

Join BII’s recognized excellence in creating, fostering, and maturing start-up and spin-out companies within human health, planetary health and societal resilience.

-

1 year programOpen Call

Venture Lab

Early-stage start-upsHelps early-stage start-ups accelerate their journey towards validated venture. Up to DKK 4M funding.

Learn more -

3 year program

Bio Studio

Early-stage start-upsSupports world-class entrepreneurial academic researchers in translating their science into innovative products and solutions. Up to DKK 7,86M funding.

Learn more -

6 months

Quantum Lab

Early-stage start-upsSupports early-stage quantum technology startups in collaboration with DIANA.

Learn more

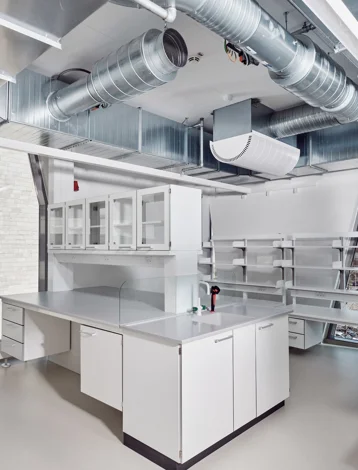

Need a lab & office space?

BII offers plug-and-play office and laboratory space to innovative start-ups and corporates.